Improving Thermal Plant Productivity for one of the world’s top 10 energy companies by accelerating mitigation actions 20x faster

The Challenge

Our client faced a number of challenges in their workplace safety processes, including checklists that were lengthy and subject to cognitive bias. Supervisors had limited visibility and, at times, insufficient data to take appropriate action on last-minute risks, safety walk reports and hazards. They wanted to simplify safety reports and create a proactive safety culture.

The Solution

We delivered our simple-to-use Health & Safety Solution in under 6 weeks. We simplified the risk assessment processes. By enabling rich multimodal data capture and providing an AI-enabled supervisory interface, the client could review risks/ hazards and close the loop in near real-time.

“Deploying the Vyn solution was easy: operators on sites adopted the tool very quickly. Vyn solution influences cognitive behavior of operators putting them in cerebral active mode favoring vigilance and decision making towards risk management.”

– Head of HSE

How did we do this? Read the full case study to find out.

The Outcome

Heightened awareness and sensitivity to workplace safety & 20x faster incident response time

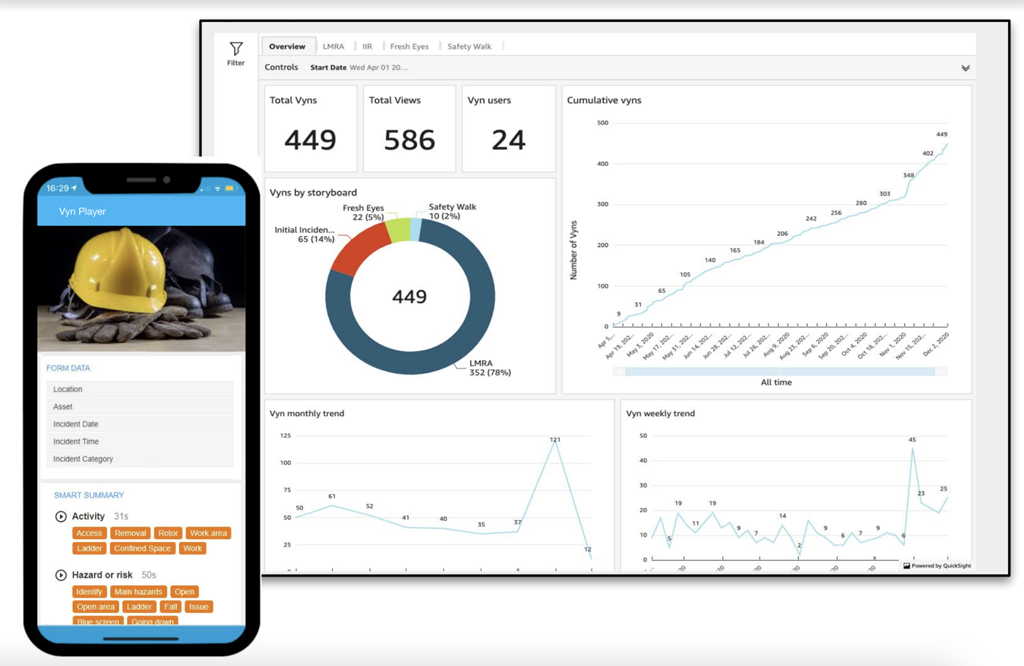

With smart, multimodal field data capture, field workers became the ‘eyes and ears’ for risk assessments and safety spotting. Digitising the end-to-end health and safety process resulted in time saved due to faster actions. With increased visibility of jobs and near real-time data dashboards, managers were 20x quicker in their response to the reported risks.

Read all the outcomes from the complete case study to find out how you can also realise 10x ROI.

If you are a Vyn customer or Vyn user, we welcome you to join the community. If you are not one (yet), let’s change that.