Vyn in Safety & Asset Management

Vyn’s Anomaly Detection AI automatically checks for PPE guideline compliance, protection barriers, and other regulatory requirements for industries globally. Deliver critical safety information across your organisation with Vyn SmartVideoNotes.

Future-proof Your Teams

A safer, healthier workforce will save you time, money, and create a safety-first culture. By using Vyntelligence, you can share expertise faster, prepare for hazards effectively, and solve problems quicker.

Vyntelligence embeds a self-audit culture where workers place as much importance on work quality as the quality inspector.

Vyn’s Anomaly Detection AI automatically checks for PPE guideline compliance, protection barriers, and other regulatory requirements for industries globally.

- Predict Risks

- Raise alerts for timely resolution

- Improve quality and safety in field workforce activities

- Give Health & Safety the recognition it deserves

- Create a proactive safety culture, sustainably

Business Impact Delivered

acceleration of process completion

increase in number of Safety Walk Reports

increase in Reporting of Near Misses

increase in number of Safety Walk Hazards observed

Use Cases

Vyn for O&M Asset Inspections

Carry out planned & unplanned maintenance, asset & safety inspections remotely – saving time, costs and carbon miles

Vyn for Proactive Safety Culture

Assure both Process & Occupational Safety with better situational awareness and AI-powered feedback & leading indicators

- Near Miss Reporting

- Last Minute Risk Assessment

- Spot Checks

- Fresh Eyes

The Vyn Advantage

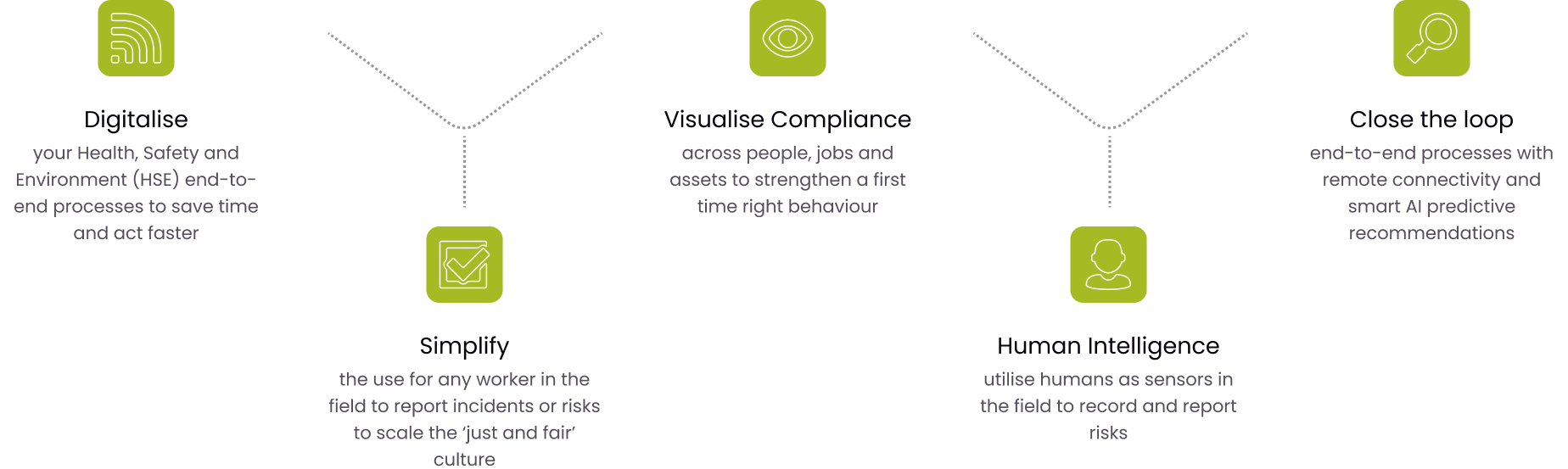

Simplify Capture for any worker in the field to identify incidents or risks to scale the ‘just and fair’ culture

Digitalise Processes in your Health, Safety and Environment (HSE) to save time and act faster

Enhance Compliance across people, jobs and assets to strengthen a first time right behaviour.

Zero Accidents. Faster Incident Response and Corrective Action and Resolution.

Embed a safety and learning culture with First Time Right inspections

Enable preventive action by detecting and acting on leading safety indicators

Vyn for Safety Risk Assessments

Quality

High quality processes in place will help to build a culture of safety. Do I have the right tech? Does my team have the right training?

Standardisation

Safety is as weak as its weakest link. Knowledge of the minimum standards is crucial.

Coverage

Ensuring full application of & contribution to the holistic safety culture across your sites.

Participation

Get as many workers adopting the processes. First steps in building a proactive culture.

Users and clients love to Vyn Sustainably

“Vyn for Safety simplified our HSE process, enhanced our incident response time and is helping to embed our Fair & Just safety culture. We appreciate Vyn’s close coordination and regular support for continuous improvement according to our needs.”

Syed Kamran

Thermal Power Plant GM

“We’re certainly seeing differences in terms of getting richer data on the vehicles and insights on coverage. Vyn works well because our field workers are taking more ownership of the responsibility they have.”

Lucy Thomas

Group Chief Scientist and MD Africa

Leading power business in Asia Pacific

“Vyn has been able to transform our processes from manual to digital… It took us just 4 weeks to deploy the technology”.

Executive Sponsor

Power Business, Asia Pacific

“The new process gives others a good insight into the job you are doing and lets you clearly show any hazards or risks.”

Chris Hogg

Meter Technician